cost-effective to keep the total price competitive easy to understand and work on for novice and experienced collectors alike reliable, durable (withstand 100 hours minimum testing) sized to fit within a box the size of an EK With that overcome, I had to source electrical components that are: I designed a small and simple mechanism inside the box to accomplish that. drive types so engine timing adjustment is performed as with the EK. Smaller batteries may work as well, but what I've found so far won't fit inside and still give the desired performance.Ī huge challenge was to make the device work with all three mag. Now, a small $5 lantern battery will operate my device (which I call the "SPARKBOX") for a long time without fail. Back in the day a magneto was attractive, in part, to get away from the poor endurance of dry cells. However, getting everything to fit was like stuffing 10 lbs into a 5 lb box. I continually pursued that goal as part of the design. Great comments and I agree, a completely self contained unit would be ideal. I’d be happy to answer your questions here, by p.m. You can find more info at our website (). It eliminates EK problems like "it works on the bench but not on the engine."

#SPARKBOX EK ALTERNATIVE PLUS#

However, as others have suggested- it’s all brand new, it makes a good backup ignition plus a test device to rule out magneto problems.

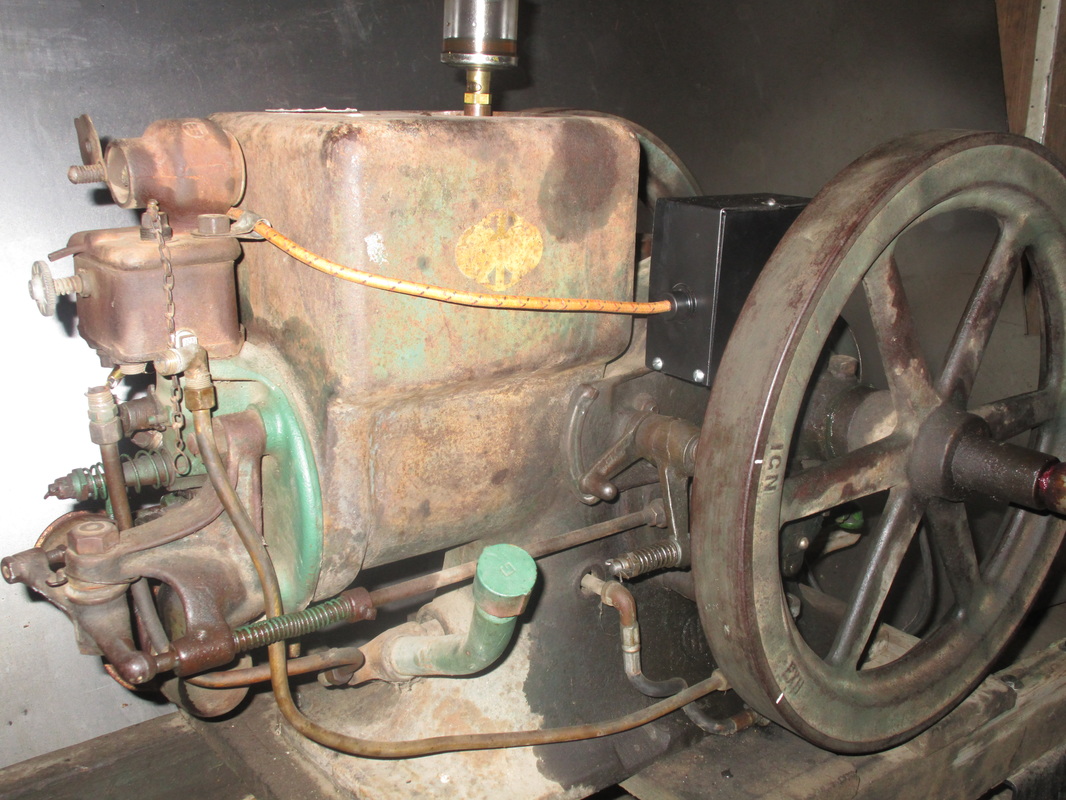

I realize the purist may scoff at a battery powered EK alternative or say “why not just buy an EK and rebuild it” etc. I designed it to keep the price competitive with a used EK. The unique mechanism inside enables it to work on all mag drive types. It tolerates mag drive wear and works equally well on my different engines. It uses 6 volt external (lantern) battery with a simple coil, condenser and microswitch circuit. The device mounts like the EK and is the same size. Over the last 15 months I've invested many hours in engineering and experimenting to refine a solution suitable for others. Researching Stak and elsewhere, I found I was not alone in this situation and eventually decided to develop a true EK alternative that works on all engines that use the EK. With limited budget and short on time, I just wanted to fix the engine enough to run. Since I didn’t have a working magneto, I rigged up a buzz coil arrangement. Several years ago I acquired my first engine that uses a Wico EK, an Economy S.

0 kommentar(er)

0 kommentar(er)